When it comes to belt conveyors, they may vary in size and shape depending on what is being conveyed. With that being said, there are several components of conveyors that carry across the board. In this article we are going to cover those parts, how they interact, and how energy is transferred to move materials.

The Frame

Frames are the functional structure that holds all of the moving parts together. This is crucial to ensure safe and efficient operation. The frames vary based upon which kind of conveyor system you are running but are generally maid of aluminum, stainless steel, or formed metal. Since this structure HOLDS the moving parts, it is not responsible for any transferring of energy.

The Drive Unit

The drive unit is a motor that generates the energy for the entire conveyor. Its soul purpose is to ensure that the conveyor is running. All drive units consist of controls and one of three kinds of drives:

End Drive - This drive consists of a motor that is used to power one of the end pulleys. End drives are usually located at the discharge end of the conveyor so that it pulls the belt/chain over the pulley.

Center Drive - Center drives are located anywhere on the frame besides the end. Despite the name, the motor can be mounted anywhere and not just the geometric center. There are usually three dynamic pulleys that are involved with this kind of drive unit. The drive pulley is in the middle and is usually larger in diameter than the others. There will also be two tail pulleys on either side of the conveyor towards the end.

Internal drive - This is the only drive where the motor is inside the pulley. This is a big difference compared to the other two that have the motor outside of the pulley. Internal drives are often referred to as internal drive drum motors. These pulleys can be placed anywhere on the conveyor but are most commonly found on the end. Belt conveyors and plastic modular chain are the most common applications for internal drive drum motors.

When referencing any drive outside of internal drives, you need to determine if it is direct or indirect. This refers to how the motor engages with the conveyor. When a drive is direct it means the the motor is attached to and directly powers the drive pulley. This option is always less complex and more economical. Indirect drives have the drive box mounted somewhere off of the drive pulley. A drive train is then used to transfer energy from the motor to the drive pulley. A drive train can consist of a series of gears and sprockets or timing belts and chains that are attached to the rotor on the pulley.

Rotors

Rotors are not necessarily involves in every conveyor system. However, they are needed when the system is indirect and using a belt or chain. This is a wheel that is attached to the outside of the pulley. A transmission belt then loops around this wheel and another corresponding wheel on the motor. When it comes to these transmission belts, it is crucial for there to be friction between the rotor belt and the wheel. Without friction, the belt would slide and energy would not be transferred from the motor to the pulley. Click here to read more on which belt cover provides this. Rotors could also be sprockets instead of wheels when using chains instead of belts.

Pulleys

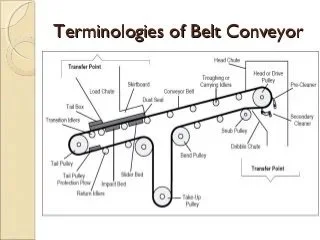

Pulleys and rollers are tubes that are attached to the frame and are used for several different purposes. The difference between a pulley and a roller is that a pulley is dynamic and can be used to change the direction of the belt. These tubes can be placed anywhere needed on the frame and there are always at least two; the drive pulley and the tail pulley.

Drive Pulleys

These pulleys are in someway attached to the motor and are used to transfer energy to the belt and drive it. Drive pulleys have the option to move at a constant speed or a variable speed depending on the needs of the facility. When it comes to direction, these pulleys need to move in the same direction as the tail pulley for the system to work. These pulleys (along with most others) have the option the be flat faced or crowned.

Drive pulleys are usually:

Tail Pulley

Tail pulleys are located at the end of the conveyor bed. Their purpose is to drive the belt back to the drive pulley. You will usually have one when you are using an end drive and two when using a center drive. Tail pulleys can be powered by internal bearings (like internal drive drum motors) or they can be mounted on external bearings like direct drive systems. It is crucial to make sure that these pulleys are running in the same direction as the drive pulley.

Idle Pulley/Rollers

These are any sort of tube that is not dynamic. Rollers support materials on the conveyor as the material moves along the belt and supports the belt during its return. Despite the terms being interchangeable, idler pulleys most often refer to a tube that does not support conveyed material.

Tension Pulley/Snub Pulley

Tension pulleys are a form of tail pulley that can have it’s position adjusted. The point of this is to bring slack out of endless belts for an easy installation. Snub pulleys are also used to increase the tension on the belt. The only difference between this and a tension pulley is that it cannot be adjusted. Snub pulleys also increase belt traction.

Belts

If you want a deeper dive on the different kinds of conveyors belts click here and here. We also have an article that covers conveyor belt pricing across the industry and another article that covers high temp conveyor belts. Now that we got the plugs out of the way, let’s talk about how they work within the conveyor system. Due to friction between the belt and pulley the belt stays attached and energy is transferred from the pulley to the belt. This allows the belt to move and in turn move the material being conveyed. Despite all of the materials that are used to make conveyors belts, they generally have at least two layers. The first layer is gives the belt structure and the proper coefficient of friction for the pulley. The second layer creates friction and traction with the material that is being conveyed. The belt support system is crucial. Therefore it is important to feed the belt through the conveyor system properly and to have the right amount of tension, rollers, and pulleys. Belts will tend to sag if there is not enough support.

Sources

https://www.iqsdirectory.com/articles/conveyor-belts.html?msID=decce3f8-2471-4f6f-bca7-7053dca69cdb

https://6river.com/what-is-a-conveyor-system/

https://www.aec-carolina.com/blog/belt-conveyor-vs-live-roller-conveyor/

https://www.thomasnet.com/articles/materials-handling/all-about-overhead-conveyors/

https://www.pneumaticconveyingsolutions.com/blog/what-is-pneumatic-conveying/

https://www.powderbulksolids.com/chemical/chemical-leak-reported-indorama-plant

https://www.solidswiki.com/index.php/Chute_Conveyors

https://www.dornerconveyors.com/solutions/magnetic-conveyors

https://dgs-ps.com/meatprocessing/buffer-conveyor/

https://www.thomasnet.com/articles/materials-handling/all-about-vibrating-conveyors/

https://en.wikipedia.org/wiki/Screw_conveyor

https://www.bastiansolutions.com/store/belt-over-roller-conveyor/rb/

https://www.elixirphil.com/types-conveyor-belts-applications/

https://feeco.com/incline-conveyors-vs-steep-incline-conveyors-whats-the-difference/

https://www.stilesenterprises.com/belt_flat_texture.html

https://www.miprcorp.com/conveyor_belts/filter-belts/

https://www.miprcorp.com/wp-content/uploads/2017/04/Filter_belts.pdf

https://www.miprcorp.com/wp-content/uploads/2017/04/Wire_cloth_catalog.pdf

https://www.titanconveyors.com/products/hinged-steel-belt

https://www.solidswiki.com/index.php/Sandwich_Belt_Conveyors

https://www.indiamart.com/proddetail/sandwich-belt-high-angle-conveyor-20556918533.html

https://durabelt.com/antistaticinfo.php

https://www.esbelt.com/en/project/anti-static/

https://www.ibiuk.com/how-conveyors-work.html

https://www.semcor.net/blog/how-do-conveyor-belts-work/

https://www.lacconveyors.co.uk/how-conveyor-systems-work/

https://www.mknorthamerica.com/Blog/conveyor-drive-types/

https://heinrichbrothers.com/product/conveyor-pulleys/

http://www.sparksbelting.com/blog/crowned-pulleys-which-option-is-right-for-you

https://www.ppi-global.com/product/mine-duty-drum-pulley/

https://www.ppi-global.com/product-lines/pulleys/wing-pulleys/

https://www.slideshare.net/ashishjain033/belt-conveyor-system-118133522