The other day, I was identifying a customer’s fitting and came across something that I have never seen before. A flange fitting with a clamp that only had two bolt holes. I spent all day measuring it and trying to figure out what it was. After some research, I discovered it was an old Code 62 fitting. That gave me the idea to break down the differences between the Code 61, the Code 62, and the supercat fitting.

There are a lot of other flange fittings such as; JIS, Komatsu, and supercat. However the Code 61 and Code 62 are the most common. All flange fittings are unthreaded but the flange head has an O-ring with a hole in the center that matches the port of the machine. The O-ring is compressed by the flange head and the flat surface with a piece of metal that is bolted over the fitting and on to the machine. Majority of these flanges are kept in place using four bolts, however, some older fittings may only have two.

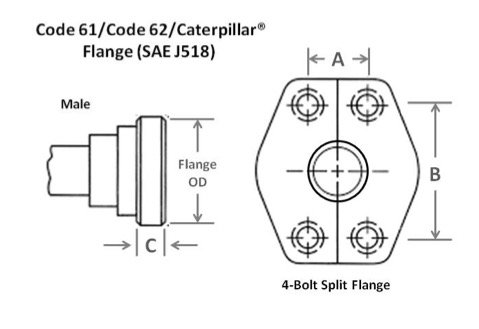

The a lot of Flange fittings look the same but there are small dimensional differences between the Code 61 and Code 62. For instance the hole in the center of the flange on a ½” code 61 will be different than the hole on a ½” code 62.

The best way to tell between the two fittings is the 4 holes where the bolts go. The bolts on a code 61 won’t line up with the holes on a code 62. With that being said, NEVER DRILL NEW HOLES. This is due to the PSI difference. Code 61’s range from 500-5000 PSI but usually never go over 3000 PSI. Code 62, despite hose size is always rated to 6,000 PSI.

The supercat is the same as the code 62 in all aspects except the thickness. The thickness on the code 62 will range from .31” for the ½” ID fitting all the way up to .5” for the 2” ID fitting. The supercat flange head will the .56” thick across the board, no matter the size of the fitting. The Komatsu fitting is the same as the code 61, however, the O-ring is thicker.

With all of that being said, here are the steps to determining the right fitting.

1. Make sure the hole of the machine matches the hole on the fitting

2. Make sure the bolts on the clamp line up with the holes on the machine.

3. Make sure the O-ring on the old fitting matches the one on the new

4. If the fitting is .56” thick, use a supercat instead of a code 62