When it comes to feeder belts, there are a lot of different materials, brands, and characteristics that differentiate belts. It can be overwhelming. The point of this article is to compare all of the different brands and the materials sold by each brand. This way, you’ll make the best purchase for your machine.

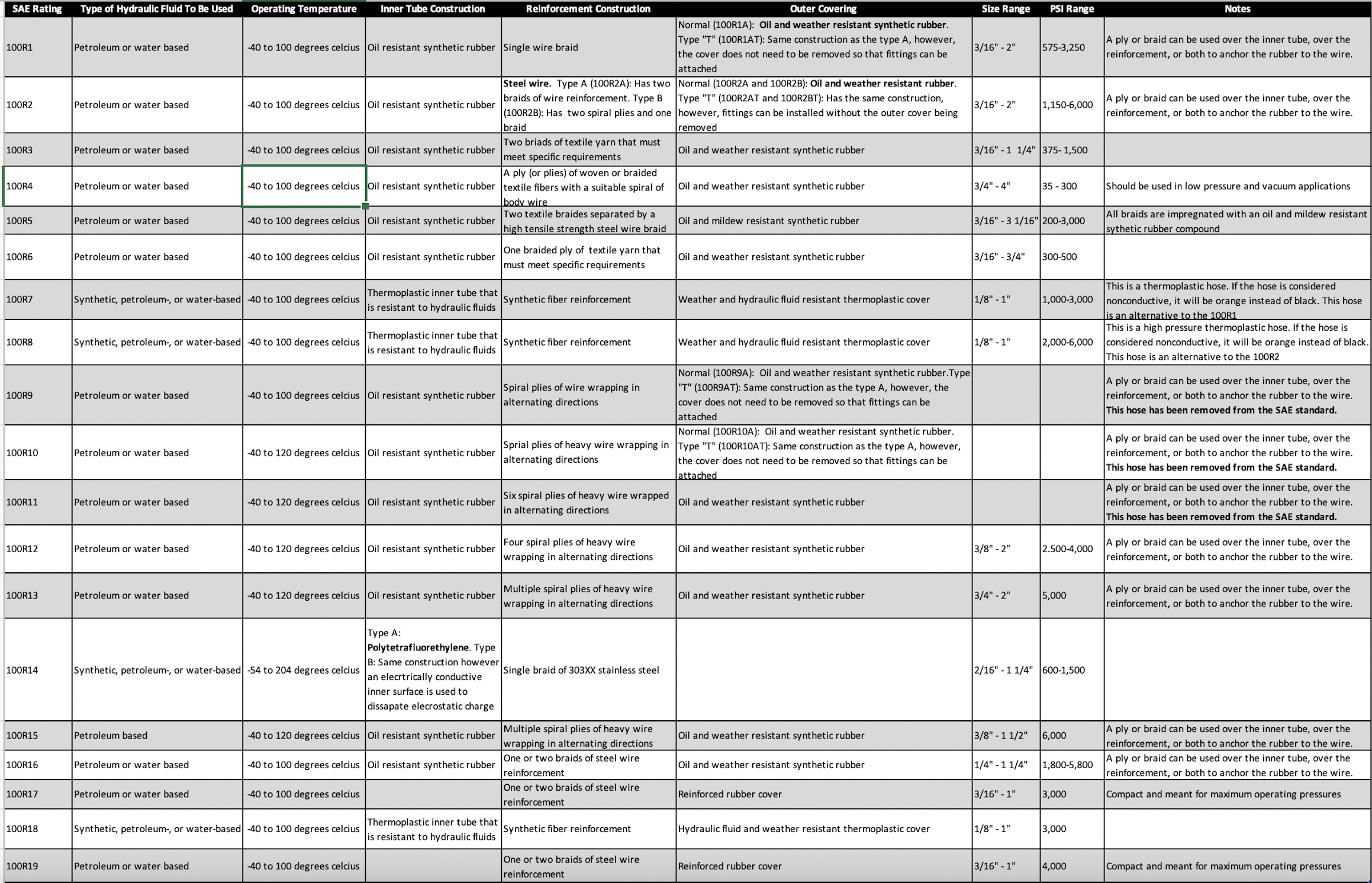

SAE Rating Guide

When you look at the layline of your hose and see an SAE rating, you may ask yourself,” What does that mean?” Long story short, this rating is used to tell you several things about the hose:

What hydraulic fluid to use.

What the hose is made out of.

The temperature that the hose can operate in.

The size range of the hose.

Other crucial facts

Bias and Hybrid Lacing: What Makes Them So Great?

In previous articles we covered splicing and mechanical splicing (or lacing) . There are two more kinds of lacing that need to be mentioned. These each have qualities of one or both of the previously mentioned splices but are tweaked for specific benefits and to solve specific problems.

Which Mechanical Splice Is The Best?

Traditional lacing (also called straight splicing or standard lacing ) is where a mechanical fastener is attached to each end of the belt and joined with a pin that goes through the center. The pin that joins the lacing can be removed at any time so that the belt can be removed from the machine for cleaning or other purposes. The lacing and pins can be made out of a variety of materials, such as stainless steel and polyurethane, to fit the certain applications. Out of all of the lacing methods this is generally the fastest, easiest, and most inexpensive. When it comes to installing the lacing, you need to square the belt. Check out the video below for a step by step demonstration on how to do so.

Thermoplastic vs Braided vs Spiral Hose: Which Is Better?

When it comes to hydraulic hose, there are a lot of different options for varying applications. Most hoses are made of synthetic materials, natural fibers, or metal wire. Covers then change to fit the conditions that the hose will be used in. One also needs to keep in mind the categorization of pressure ratings. High pressure is 1500-6000 PSI, medium pressure is 300-3000 PSI, and low pressure is 300 PSI or less. With all of that being said, when it comes to most heavy duty equipment such as excavators and bull dozers, there are three main kinds; thermoplastic, braided, and spiral.

3 Common Problems In Conveyor Systems (and how to fix them)

Conveyors are built to move materials from point A to point B. However, this is not always the case. Sometimes issues in the system can lead to shut downs, damage to the system, or even hazardous conditions for workers. This article is going to cover the three most common forms of conveyor issues along with reactive and preventive measures to fix them.

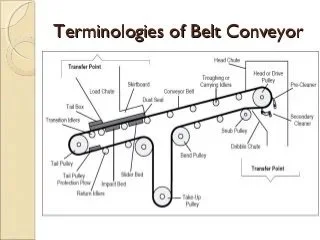

How Do Conveyors Work?

When it comes to belt conveyors, they may vary in size and shape depending on what is being conveyed. With that being said, there are several components of conveyors that carry across the board. In this article we are going to cover those parts, how they interact, and how energy is transferred to move materials.

What Are The Types Of Conveyor Belts? (Part 2)

What Are The Types Of Conveyor Belts? (Part 1)

How To Choose The Right Conveyor System

As you can see from our two blog posts on the different kinds of conveyors (What Conveyor Is Right For Me 1 and What Conveyor Is Right For Me 2) there are a lot of different choices. So how do you go about choosing the best one for your operation? This article is going to be a step by step guide on how to choose a conveyor system for your business.

What Type Of Conveyor System Is Right For Me? (Part 2)

Conveyors are material handling systems that are designed to move all sorts of materials, parts, and supplies. The purpose of each of these systems is to save business on time, energy, and cost. When it comes these conveyor systems, there are many different kinds. Each has their own “pros” and “cons.” This series of articles is going to cover all of the major kinds of conveyor systems and which systems are best suited for certain operations. Factors that determine this are costs, energy consumption, materials being conveyed, and more. Here is the second part to the series where we help you determine which conveyor is right for your operation

What Type Of Conveyor System Is Right For Me? (Part 1)

Conveyor are material handling systems that are designed to move all sorts of materials, parts, and supplies. The purpose of each of these systems is to save business on time, energy, and cost. When it comes these conveyor systems, there are many different kinds. Each has their own “pros” and “cons.” This series of articles is going to cover all of the major kinds of conveyor systems and which systems are best suited for certain operation. Factors that determine this are costs, energy consumption, materials being conveyed, and more. With out further delay, lets determine which conveyor is best for your business.

Polyester Vs Elastic: Which Core Is Best For Your Paper Operation?

Polyester and Elastic are two core materials that are crucial to the printing, paper converting, and mail processing industries. In the printing industry, these materials are used for transporting, stackers, bookbinding, sheeters, and more. When it comes to paper converting they are used on folder-gluers, corrugators, and multiwall bags.

Which Splice Is Best For You?

Kelvar vs. Fiberglass: Which High Temp Conveyer Belt Is Better?

When it comes to high temperature conveyer belts there are two common choices for cores that can be used, Kevlar and Fiberglass. Kevlar is organic or synthetic fibers that do not melt or ignite in conditions where there are normal levels of oxygen. These kind of belts are commonly used in the aluminum extrusion industry as a cooling belt. When it comes to the resistance to certain materials, Kevlar is resistant to most oils and fats including those that come from plants, animals, and minerals. Kevlar can withstand continuous ambient temperatures of up to 350°C and contact temperatures of 450°C.

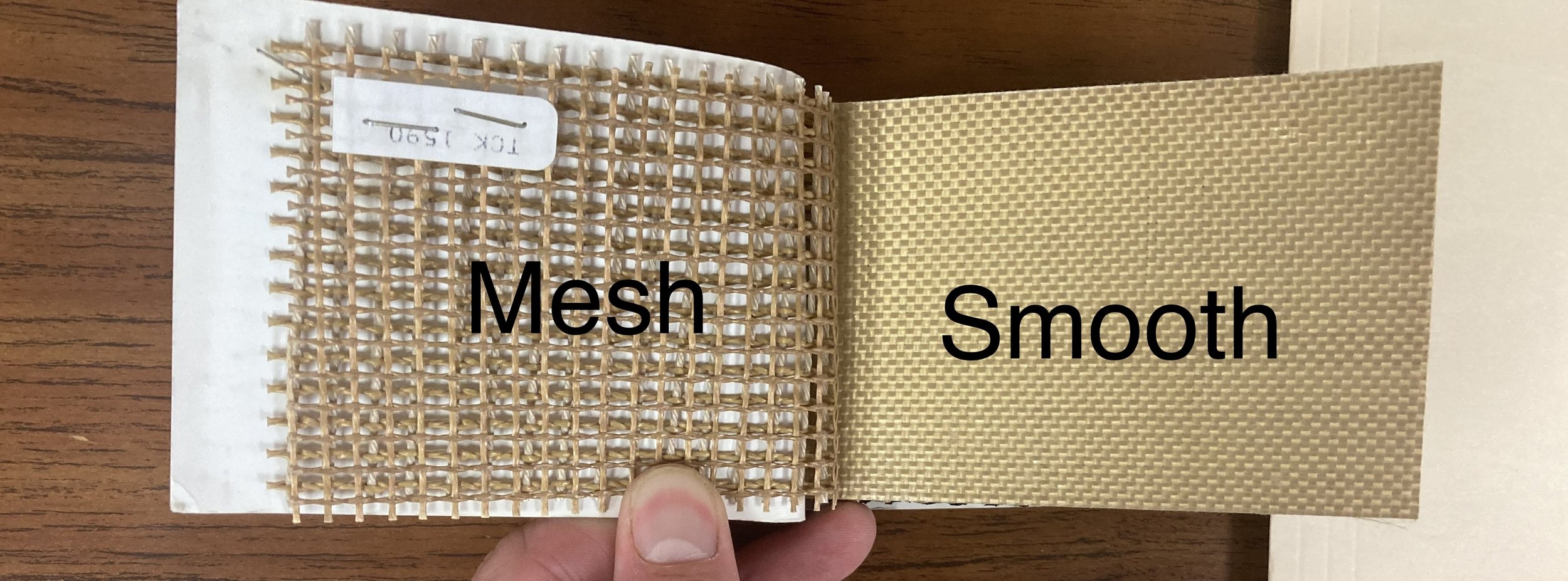

Fiberglass yarn is a material that has a very high strength to weight ratio, twice that of steel. When it comes to fiberglass there are two kinds, S-glass and E-glass. S-glass is a lot stronger than E-glass but is also more expensive. These belts generally come in one of two forms, mesh and smooth.

Two Types Of Fiberglass Belts

In reference to temperature resistance, fiberglass is stable in the range of -73 to 260°C. This material with retain 50% of its strength at 370°C and 25% of its strength at 537°C. Fiberglass is used often in the packaging, handling, and drying applications.

So what are the differences? What are the similarities? To start, both materials are; odorless and taste free, can be FDA compliant, have low moisture absorption, are rot-proof, and are stretch/shrink proof (fiberglass elongation is less than 1% for example). When it comes to strengths these materials start to differ. S-glass has a higher tensile strength (strength over area) than Kevlar but E-glass is weaker than Kevlar. You also might notice that the ability to withstand continuous ambient temperature is also different. Kevlar can operate in almost 100°C hotter than Fiberglass. Lastly, Kevlar is sensitive to acids, salts, and ultraviolet radiation. This could require you to have specific is covers for the Kevlar if your belt is being exposed to this.

Hopefully this gives you a better idea of the differences between the two materials. Make sure to keep this in mind when it comes to your next purchase of a high temperature conveyer belt. You always want to make sure that you have the best product for your situation.

Sources:

https://www.sciencedirect.com/topics/engineering/kevlar

https://en.wikipedia.org/wiki/Aramid

https://www.vetrotextextiles.com/technologies/fiberglass-manufacturing/fiberglass-properties

https://www.phelpsgaskets.com/blog/fiberglass--types-properties-and-applications-across-industries

https://www.youtube.com/watch?v=KHXVf0SaJpA

Industry Innovation: The Accu-link V-Belt

Which Transmission Belt Cover Is The Best?

In previous articles, we discussed the cost drivers when it comes to transmission belts and the differences between the cores that are found in this kind of belting. Based on the title, you can see that there are three common covers that are found on transmission belts; leather, rubber, and tempered polyurethane (TPU). In this article, we are going to discuss the differences between these three coatings.

Which Transmission Belt Core Is The Best For You? (Kevlar vs. nylon vs. polyester)

In a previous article, we discussed how cores are generally priced. Nylon is cheaper than polyester, which is cheaper than Kevlar. This then begs to question, what is the difference between them? Which one is right for me? In this article, we are going to discuss and compare the common cores that are found in transmission belts.

How Much Do V-Belts Cost?

In our previous article, we discussed the basics of V-belts. Now it is time for the fun part, the costs drivers. These belts range from a five dollars all the way up to a couple thousand. When it comes to this style of belting the dimensions are the biggest cost driver. The longer the belt, the more expensive that it is going to be.

What Is a V-Belt?

V belts are the most common form of transmission belt found across the board. They are used in many kinds of machines across various industries. Some examples of which are agricultural equipment, HVAC, lawn/garden equipment, and general transmissions. With that beings said, you might be asking yourself a few questions when trying to figure out which V-belt is right for your equipment. This article is going to go over the basics so that you can make an informed decision on which V-belt is right for you.