When it comes to high temperature conveyer belts there are two common choices for cores that can be used, Kevlar and Fiberglass. Kevlar is organic or synthetic fibers that do not melt or ignite in conditions where there are normal levels of oxygen. These kind of belts are commonly used in the aluminum extrusion industry as a cooling belt. When it comes to the resistance to certain materials, Kevlar is resistant to most oils and fats including those that come from plants, animals, and minerals. Kevlar can withstand continuous ambient temperatures of up to 350°C and contact temperatures of 450°C.

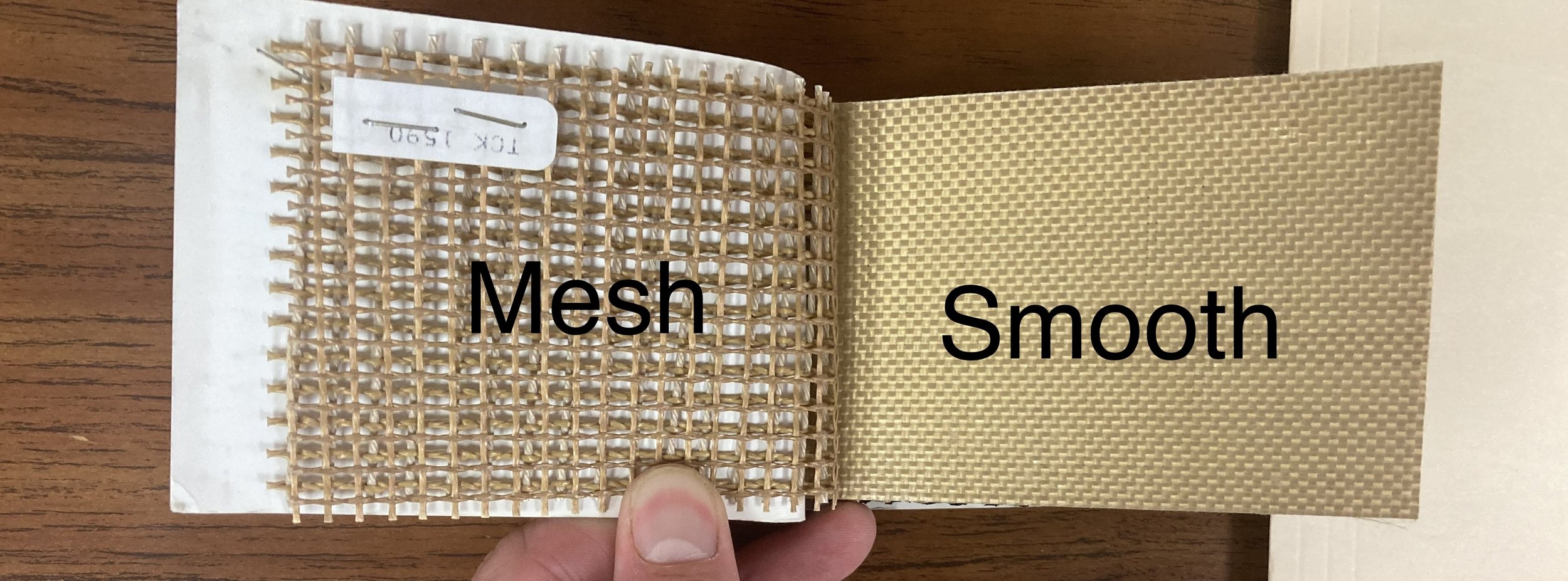

Fiberglass yarn is a material that has a very high strength to weight ratio, twice that of steel. When it comes to fiberglass there are two kinds, S-glass and E-glass. S-glass is a lot stronger than E-glass but is also more expensive. These belts generally come in one of two forms, mesh and smooth.

Two Types Of Fiberglass Belts

In reference to temperature resistance, fiberglass is stable in the range of -73 to 260°C. This material with retain 50% of its strength at 370°C and 25% of its strength at 537°C. Fiberglass is used often in the packaging, handling, and drying applications.

So what are the differences? What are the similarities? To start, both materials are; odorless and taste free, can be FDA compliant, have low moisture absorption, are rot-proof, and are stretch/shrink proof (fiberglass elongation is less than 1% for example). When it comes to strengths these materials start to differ. S-glass has a higher tensile strength (strength over area) than Kevlar but E-glass is weaker than Kevlar. You also might notice that the ability to withstand continuous ambient temperature is also different. Kevlar can operate in almost 100°C hotter than Fiberglass. Lastly, Kevlar is sensitive to acids, salts, and ultraviolet radiation. This could require you to have specific is covers for the Kevlar if your belt is being exposed to this.

Hopefully this gives you a better idea of the differences between the two materials. Make sure to keep this in mind when it comes to your next purchase of a high temperature conveyer belt. You always want to make sure that you have the best product for your situation.

Sources:

https://www.sciencedirect.com/topics/engineering/kevlar

https://en.wikipedia.org/wiki/Aramid

https://www.vetrotextextiles.com/technologies/fiberglass-manufacturing/fiberglass-properties

https://www.phelpsgaskets.com/blog/fiberglass--types-properties-and-applications-across-industries

https://www.youtube.com/watch?v=KHXVf0SaJpA