Belt tracking issues can disrupt your conveyor system and lead to unnecessary shutdowns. In addition, it can lead to belt damage if the belt mis-tracks into a conveyor belt frame causing damage to the belt that often leads to the need for replacement. To keep a belt tracking properly a simple solution many conveyors systems use is a V-guide. This article is a guide to all the things you need to know about your v-guided conveyor belts.

What is a v guided belt?

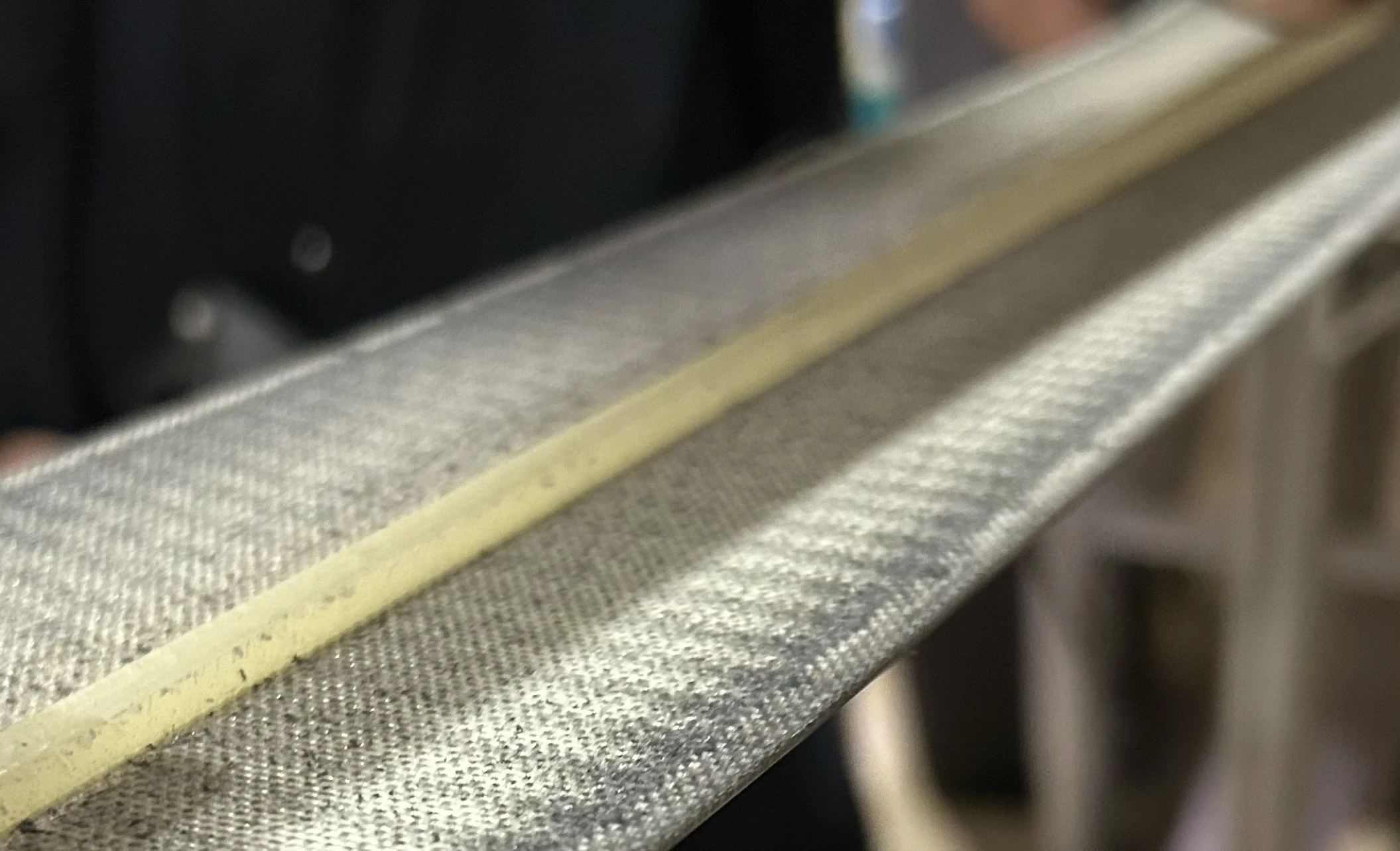

V guided belts employ a sophisticated design that incorporates V-shaped grooves on the conveyor’s end rollers and bed plates. The design consists of a polyurethane or PVC strip (like a car's v-belt) attached beneath the belt to engage seamlessly with these grooves ensuring consistent belt alignment throughout the journey.

What are the advantages of V-guided belts?

1. Improved Tracking Consistency: The close fit between the V-guide and V-groove (typically a 1/16” gap) ensures minimal belt drift, maintaining tight control over the conveyor belt's movement. This is extremely important in applications where belts are long and narrow OR wide and short, since these types of belts are prone to inconsistent load distribution. By maintaining proper alignment, V-guides reduce wear on the belt edges, thereby extending the belt's operational lifespan.

2. Reduction in Conveyor Failures: Consistent tracking facilitated by V-guides significantly reduces the occurrence of belt misalignment and failures. This reliability enhances overall conveyor uptime and productivity by minimizing downtime associated with belt adjustments and replacements.

3. Versatility for Manufacturers Applications: Whether handling small or odd-shaped products, V-guided belts offer a level and consistent surface for efficient transfer. This versatility makes them ideal for industries requiring reliable conveyor solutions across various product types and sizes.

What are the different types of v-guides?

Profiles

Solid V-guide: Provides continuous support along the entire length of the belt.

Standard Notched V-guide: Allows flexibility and adjustment for varying belt tensions.

Deep Notched V-guide: Offers enhanced stability for heavier loads or rugged environments.

Urethane Segmented V-guide: Ensures flexibility while maintaining durability against wear and tear.

Placement of guide

Center pulley side: The guide is equidistant from each side centered on the bottom of the belt

Offset to one side: The guide is placed to one side of the belt

Dual sided v-guide: There are two guides that can either be flush with the edge of the belt or equidistant from each edge

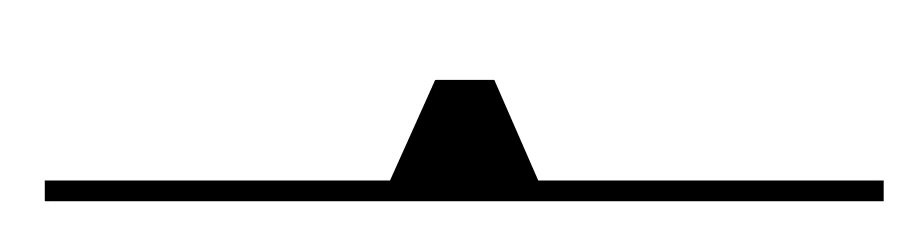

Typical guide sizes

Diagram for dimension chart above

Problems to note when purchasing v-guided belts:

They are not completely flat: To make a v-guided belt heat must be applied which can cause a small raise to your belt of less than .010”. If you are moving light or flimsy products a v-guided belt may not be the best solution.

They provide a failure point: If the v-guide strip is not added before the belt it can provide a failure point. Look for v-guided belts where the strip is seamless and made from the same material as the belt.

They will be more expensive than normal conveyor belts: The additional manufacturing necessary to make a v-guide will cost more than a conveyor belt without one. Make sure you are getting the most out of your v-guided belt by working with a Bamco representative to ensure you are getting the most durable materials and proper size.